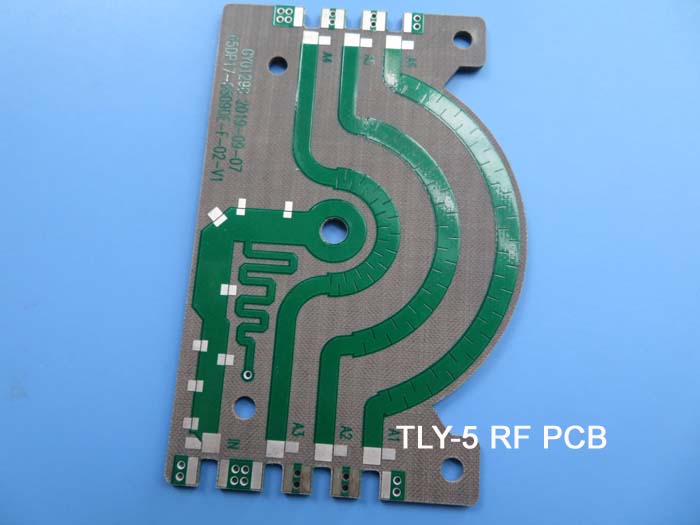

Taconic TLY-5, TLY-5-L, TLY-3, TLY-3FF High Frequency PCB Coating Options Coatings with HASL,OSP, Immersion Gold,and Tin

(Printed Circuit Boards are custom-made products; the images and parameters shown are for reference only.)

Hello everyone,

Today, we focus on high-frequency PCBs built using TLY material from Taconic Company.

Overview of TLY Laminates

TLY laminates are made from lightweight woven fiberglass, providing superior dimensional stability compared to chopped fiber-reinforced PTFE composites. This enhanced mechanical stability makes them ideal for high-volume manufacturing processes.

The low dissipation factor of TLY laminates enables effective deployment in automotive radar applications designed for 77 GHz, as well as in other antennas operating at millimeter wave frequencies.

Key Advantages of TLY Laminates

1.Dimensionally Stable:High volume fabrication becomes possible.

2.Lowest Dissipation Factor:The dielectric constant range features a dissipation factor of approximately 0.0009 at 10 GHz.

3.Low Moisture Absorption:Suitable for operation in severe environmental conditions.

4.High Copper Peel Strength:Achieves a peel strength of up to 2.32, ensuring durability.

5.Uniform and Consistent Dielectric Constant:Allows specification of the dielectric constant within a tight tolerance of +/-0.02 across most thicknesses.

Typical Applications

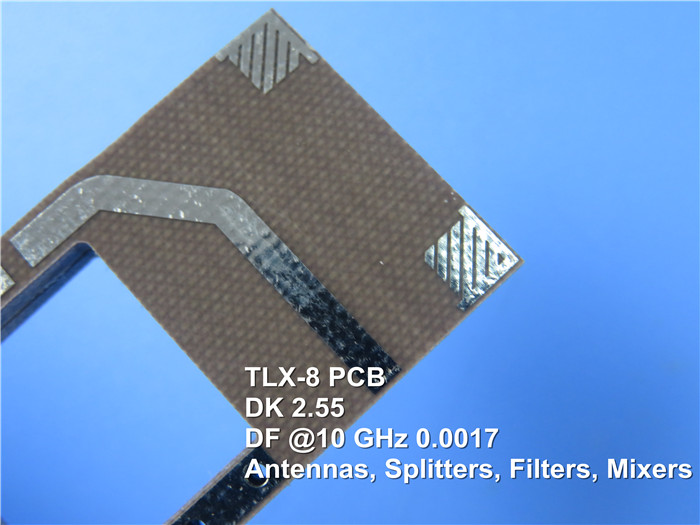

The TLX family includes various options:

- Automotive radar systems

- Cellular communication devices

- Satellite communication equipment

- Amplifiers, filters, and couplers

- LNBs, LNAs, and LNCs

- Aerospace and avionics applications

- Phased array antennas

TLY Family Overview

The TLY family consists of six members, with TLY-5 currently in stock. Other variants are available based on client requirements.

Our PCB Capabilities with TLY-5

PCB Capability (TLY-5) |

|

PCB Material: |

Lightweight Woven Fiberglass |

Designation: |

TLY-5 |

Dielectric Constant: |

2.2 |

Dissipation Factor |

0.0009 10GHz |

Layer Count: |

Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper Weight: |

1oz (35µm), 2oz (70µm) |

Laminate Thickness: |

10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) |

PCB Size: |

≤400mm X 500mm |

Solder Mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface Finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold plated etc.. |

Bicheng specializes in offering prototype, small-batch, and mass production services.

If you have any questions, please feel free to contact us. Thank you for reading!

Appendix:Typical Values of TLY

TLY TYPICAL VALUES |

|||||

Property |

Test Method |

Unit |

Value |

Unit |

Value |

DK at 10 GHz |

IPC-650 2.5.5.5 |

|

2.2 |

|

2.2 |

Df at 10 GHz |

IPC-650 2.5.5.5 |

|

0.0009 |

|

0.0009 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.02 |

% |

0.02 |

Dielectric Breakdown |

IPC-650 2.5.6 |

kV |

>45 |

kV |

>45 |

Dielectric Strength |

ASTM D 149 |

V/mil |

2,693 |

V/mil |

106,023 |

Volume Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms/cm |

1010 |

Mohms/cm |

1010 |

Volume Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms/cm |

1010 |

Mohms/cm |

109 |

Surface Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms |

108 |

Mohms |

108 |

Surface Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms |

108 |

Mohms |

108 |

Flex Strength(MD) |

IPC-650 2.4.4 |

psi |

14,057 |

N/mm2 |

96.91 |

Flex Strength(CD) |

IPC-650 2.4.4 |

psi |

12,955 |

N/mm2 |

89.32 |

Peel Stength(½ oz.ed copper) |

IPC-650 2.4.8 |

Ibs./inch |

11 |

N/mm |

1.96 |

Peel Stength(1 oz.CL1 copper) |

IPC-650 2.4.8 |

Ibs./inch |

16 |

N/mm |

2.86 |

Peel Stength(1 oz..CV1 copper) |

IPC-650 2.4.8 |

Ibs./inch |

17 |

N/mm |

3.04 |

Peel Stength |

IPC-650 2.4.8(after elevated temp.) |

Ibs./inch |

13 |

N/mm |

2.32 |

Young's Modulus(MD) |

ASTM D 3039/IPC-650 2.4.19 |

psi |

1.4 x 106 |

N/mm2 |

9.65 x 103 |

Poisson's Ratio(MD) |

ASTM D 3039/IPC-650 2.4.19 |

|

0.21 |

|

0.21 |

Thermal Conductivity |

ASTM F 433 |

W/M*K |

0.22 |

W/M*K |

0.22 |

Dimensional Stability(MD,10mil) |

IPC-650 2.4.39(avg.after bake&thermal stress) |

mils/inch |

-0.038 |

|

-0.038 |

Dimensional Stability(CD,10mil) |

IPC-650 2.4.39(avg.after bake&thermal stress) |

mils/inch |

-0.031 |

|

-0.031 |

Density(Specific Gravity) |

ASTM D 792 |

g/cm3 |

2.19 |

g/cm3 |

2.19 |

CTE(X axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

26 |

ppm/℃ |

26 |

CTE(Y axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

15 |

ppm/℃ |

15 |

CTE(Z axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

217 |

ppm/℃ |

217 |

NASA Outgassing(% TML) |

|

|

0.01 |

|

0.01 |

NASA Outgassing(% CVCM) |

|

|

0.01 |

|

0.01 |

NASA Outgassing(% WVR) |

|

|

0.00 |

|

0.00 |

UL-94 Flammability Rating |

UL-94 |

|

V-0 |

|

V-0 |